-

Welcome to N-cars.net - the largest Hyundai N car forum. Check out the model specific sections below and scroll down for country specific forums. Scroll down for i20 N, Kona N and Tuscon N forums! Check out the i30 N Bible Here!

Suspension and Chassis DIY coilovers?

- Thread starter MRunabout

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The first image shows my Apexi upper spring perch with a BC 14mm ID, 28mm length camber plate bushing.

The second is the camber plate mated to the upper spring perch

Third just shows camber plate thickness for the eBay flush mount option. I'll take a picture of the non-flush mount option tomorrow.

Fourth is showing the length of the piston rod's threaded portion and how with the upper perch, bushing, and camber plate, the threaded portion sits just about level with the top of the camber plate bearing as shown in the last picture.

The second is the camber plate mated to the upper spring perch

Third just shows camber plate thickness for the eBay flush mount option. I'll take a picture of the non-flush mount option tomorrow.

Fourth is showing the length of the piston rod's threaded portion and how with the upper perch, bushing, and camber plate, the threaded portion sits just about level with the top of the camber plate bearing as shown in the last picture.

This configuration isn't compatible with either the VN or i30N. How does this cross over to either model? This type of setup requires a complete replacement of the coilovers and strut combination and no retaining of the OEM ESC.

In fact it's no where close to what is required. What your displaying will not work with the OEM ESC configuration.

n-cars.net

n-cars.net

Both VN and i30N also have different struts, mounting points & strut carriers. Strut parts numbers are the same.

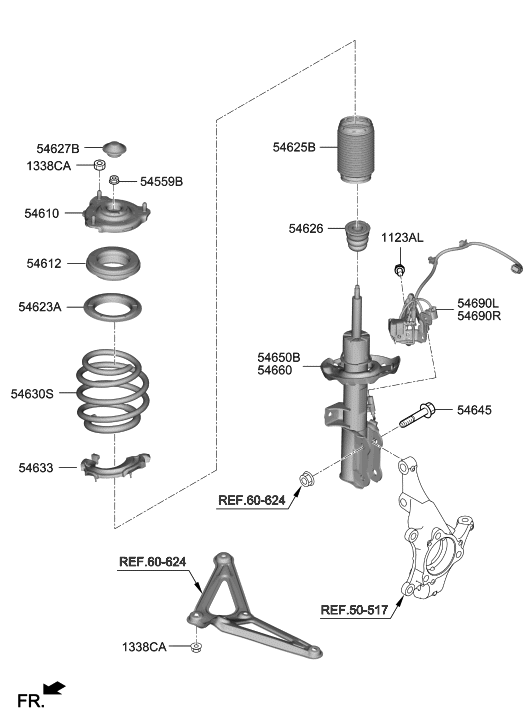

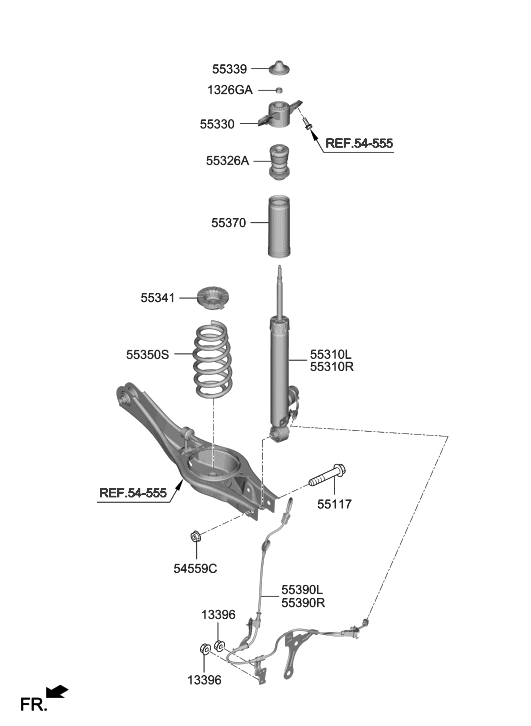

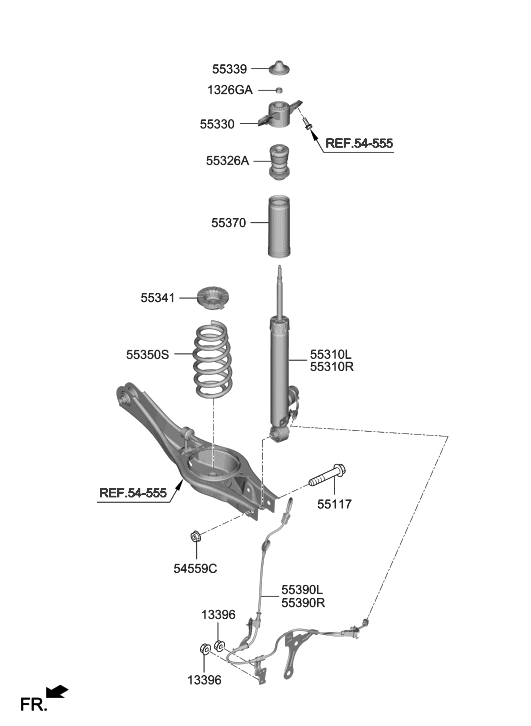

Both the VN and i30N utilize a cathedral bearing setup. With the either the VN or i30N the OEM ESC requires a progressive spring rate, with the real possibility of having to trim the bump stop as well. Due to the chassis design mounting points the camber slates need to seat into the chassis carrier mounting recess, with a pillow ball configuration. So, anything with a flat surface will not retain the necessary stability to hold the upper perch or strut securely in place under specific lateral to forward/aft suspension loading. Refer to the attachment below;

( Veloster N )/ ( i30N) Respectively

So one or the other needs to be focused on. However, what your displaying above will not be compatible with either based upon suspension dynamics and configurations.

The proper camber plate assemblies will be required for the VN and i30N due to the strut mounting points. The VN can utilize the addition of camber bolts, which are readily available. Most of this has already been covered quite extensively in other threads.

Frankly, this is not a backyard DIY project and requires specific attention to fitment and calibration. It will require the use of a suspension geometry jig and alignment tooling with the specific knowledge and understanding of suspension geometries.

A Suspension Geometry Jig is very expensive ($6K-8K), not to mention the understanding and knowledge to make sure the proper geometry is achieved and time to ensure proper alignment of the suspension components. There's far more involved than bolting on some universal camber plates, coilovers and spring kits. Then taking it to your local alignment shop and voila' your there.

This is one of the reason I ask the op specifically, how he envisioned and purposed to attain a sufficient result.

Such a project involves far more then just adjustment of a vehicle’s suspension. It is not an adjustment of the tires or wheels themselves. It's also more than just setting; camber, toe, caster and tire balancing. There is far more to proper suspension alignment, than adjusting the angles of the tires, which affects how they make contact with the road.

When you change spring rates and heights you effect more than just ride height, compression and rebound, loading and unloading of chassis components. You first have to consider; ride, road holding, and cornering as well. There are a plethora of settings associated with these three factors. These include chassis balance & overall chassis dynamics, etc. It's much more involved then is simply imagined here. None of which are being thought of or spoken about but nevertheless are extremely important and drastically affect the entire chassis.

When you change one suspension component, it affects the entire chassis. A chassis/suspension dynamics pros knowledge and understanding is required to balance the entire chassis. I can go much deeper into the finer aspect of chassis and suspensions adjustments. However it won't serve a purpose, other than to demonstrate how one change in the suspension, drastically affects the overall chassis dynamics. I learned suspension setup and attained the knowhow, over years of racing both motorcycles and cars.

It's not something to guess about or as simplistic as bolting on universal DIY suspension parts. There's always a means to the madness and a purposeful dynamic that has to be consider, for each venue and sub venue; daily road use, combined track/road use or track use. Get it wrong and you cause problems with safety, longevity and chassis/suspension performance.

I think before we get to carried aways with a backyard mechanic version of a DIY coilover project, some need to realize what is actually involved.

For example, take a look at Dan Bushell's thread ,with specific note to the Forge Motorsport prototype camber plates and what was requires to make them a viable part of the entire chassis/suspension. Post # 793 for starters.

n-cars.net

Keeping in mind,well before this, Forge Motorsport has put in a a lot of research and development of the Camber Plates alone. Something that is not being spoken about here. You can't get into specifics of any project until you understand the entire picture and what in reality, is truly involved.

n-cars.net

Keeping in mind,well before this, Forge Motorsport has put in a a lot of research and development of the Camber Plates alone. Something that is not being spoken about here. You can't get into specifics of any project until you understand the entire picture and what in reality, is truly involved.

Personally, I don't see the necessary knowledge, understanding or ability being demonstrated here. (no offense intended) There's just far more factual information to be considered and understood when engaging in such a project. Hence the term "bench racing."

In fact it's no where close to what is required. What your displaying will not work with the OEM ESC configuration.

Suspension and Chassis - Custom Front Adjustable Camber Plates for OEM Suspension

https://www.ngarage.com.au/product-page/ast-suspension-front-camber-strut-tops-i30n That price :eek: hopefully forges setup is more wallet friendly

Both VN and i30N also have different struts, mounting points & strut carriers. Strut parts numbers are the same.

Both the VN and i30N utilize a cathedral bearing setup. With the either the VN or i30N the OEM ESC requires a progressive spring rate, with the real possibility of having to trim the bump stop as well. Due to the chassis design mounting points the camber slates need to seat into the chassis carrier mounting recess, with a pillow ball configuration. So, anything with a flat surface will not retain the necessary stability to hold the upper perch or strut securely in place under specific lateral to forward/aft suspension loading. Refer to the attachment below;

( Veloster N )/ ( i30N) Respectively

So one or the other needs to be focused on. However, what your displaying above will not be compatible with either based upon suspension dynamics and configurations.

The proper camber plate assemblies will be required for the VN and i30N due to the strut mounting points. The VN can utilize the addition of camber bolts, which are readily available. Most of this has already been covered quite extensively in other threads.

Frankly, this is not a backyard DIY project and requires specific attention to fitment and calibration. It will require the use of a suspension geometry jig and alignment tooling with the specific knowledge and understanding of suspension geometries.

A Suspension Geometry Jig is very expensive ($6K-8K), not to mention the understanding and knowledge to make sure the proper geometry is achieved and time to ensure proper alignment of the suspension components. There's far more involved than bolting on some universal camber plates, coilovers and spring kits. Then taking it to your local alignment shop and voila' your there.

This is one of the reason I ask the op specifically, how he envisioned and purposed to attain a sufficient result.

Such a project involves far more then just adjustment of a vehicle’s suspension. It is not an adjustment of the tires or wheels themselves. It's also more than just setting; camber, toe, caster and tire balancing. There is far more to proper suspension alignment, than adjusting the angles of the tires, which affects how they make contact with the road.

When you change spring rates and heights you effect more than just ride height, compression and rebound, loading and unloading of chassis components. You first have to consider; ride, road holding, and cornering as well. There are a plethora of settings associated with these three factors. These include chassis balance & overall chassis dynamics, etc. It's much more involved then is simply imagined here. None of which are being thought of or spoken about but nevertheless are extremely important and drastically affect the entire chassis.

When you change one suspension component, it affects the entire chassis. A chassis/suspension dynamics pros knowledge and understanding is required to balance the entire chassis. I can go much deeper into the finer aspect of chassis and suspensions adjustments. However it won't serve a purpose, other than to demonstrate how one change in the suspension, drastically affects the overall chassis dynamics. I learned suspension setup and attained the knowhow, over years of racing both motorcycles and cars.

It's not something to guess about or as simplistic as bolting on universal DIY suspension parts. There's always a means to the madness and a purposeful dynamic that has to be consider, for each venue and sub venue; daily road use, combined track/road use or track use. Get it wrong and you cause problems with safety, longevity and chassis/suspension performance.

I think before we get to carried aways with a backyard mechanic version of a DIY coilover project, some need to realize what is actually involved.

For example, take a look at Dan Bushell's thread ,with specific note to the Forge Motorsport prototype camber plates and what was requires to make them a viable part of the entire chassis/suspension. Post # 793 for starters.

Dan_bush27 Performance blue thread

They didn't do the voting on FB??:confused: Should have it would make it not so close.:) The RX7 isn't streetable either.

Personally, I don't see the necessary knowledge, understanding or ability being demonstrated here. (no offense intended) There's just far more factual information to be considered and understood when engaging in such a project. Hence the term "bench racing."

Last edited:

Doesn't anyone has questions about safety with these kinds of "DIY projects"?

Cutting into original components, welding on some e-bay stuff, ...

What about material strenght, on road safety, ...

I think these kinds of things have no place here, but that's just my opinion.

Very few people on here have the skills or the technical knowledge to tackle these mods, but I'm sure some of them will be tempted to give it a go.

Who is gonna be responsible when something really goes wrong, let's say a strut breaks in a fast corner, car crashes, driver heavily injured (or worse)?

Cutting into original components, welding on some e-bay stuff, ...

What about material strenght, on road safety, ...

I think these kinds of things have no place here, but that's just my opinion.

Very few people on here have the skills or the technical knowledge to tackle these mods, but I'm sure some of them will be tempted to give it a go.

Who is gonna be responsible when something really goes wrong, let's say a strut breaks in a fast corner, car crashes, driver heavily injured (or worse)?

Last edited:

Yes, I've been posing this same concern over and over again.

Even welding on a spring perch has to be done in such a manner, as to accommodate the original OEM specifications and the original alloys used in it's production. Get it to hot, you burn a hole into the strut body. Don't get the right alloy metallurgy welds and it's becomes a weakened component.

Such after the fact welding, doesn't take in consideration the original assembly process either. All welding is done prior to any seals or fluids being added to the strut body. For good reason as well. Damage the strut or seals it's ruined. Utilizing a specifically designed and manufactured coil over component, is far safer and wiser than engaging in a backyard DIY project.

The Attack Team Hyundai i30N has Hyundai engineering backing and support. It's a track based race car with an approved racing modification, not DOT, MOT & TUV certification. When you start playing around with suspension components and modifying them, you create all sort of unknown issues.

All this has to be considered. You also have to consider your Insurance requirements, let alone you autos warranty. Have an accident due to failure in a suspension component, that was due to improper DIY modification and see if your insurance pays off.

Daily road use brings out the worst in parts, not road racing. You get it wrong, you endanger yourself and others as well. A complete understanding of the entire concept is required before you jump off the cliff, so to speak. That isn't and hasn't happened here.

I'm making a point about; DOT, MOT, & TUV safety requirements, original OEM construction, purposeful experience, understanding and attempting to look at such a project from a realistic overall perspective. I completely understand the concept but I also know the entire spectrum of issues and ramifications of engaging in such a project. Otherwise, I've been there done that, with a lot of prior first hand knowledge, understanding and experience.

This is not something you can do in your spare time, in your garage, with limited knowledge or a ricers perspective. (no offense intended, it's a colloquialism) please read below.

www.urbandictionary.com

There's far more involved, and we haven't even scratched the surface. I'm attempting to discuss them and stay on topic as well. All in all, you're looking at twice the expense of purchasing a specifically designed kit, on top of all the other requirements for the suspension/chassis adjustments.

www.urbandictionary.com

There's far more involved, and we haven't even scratched the surface. I'm attempting to discuss them and stay on topic as well. All in all, you're looking at twice the expense of purchasing a specifically designed kit, on top of all the other requirements for the suspension/chassis adjustments.

You're already aware of the issues that came up with ST Conversion that @Bullet installed & experienced. They were minor even for a reputable manufacturer. This is just some of the small issues that must be contended with. Due diligence hasn't been accomplished or even spoken about. So, I'm doing so with directness and peaceably as before.

n-cars.net

Such a DIY project is impractical, uncertified and simply dangerous, especially in the wrong hands.

n-cars.net

Such a DIY project is impractical, uncertified and simply dangerous, especially in the wrong hands.

Personally, I don't believe the N-Cars.net Forum needs such a liability or as a proponent of such as hypothetical DIY project, considering the lack of overall expertise involved. Again this is part of an overall perspective, I'm referring to directly. Not a horse with blinders viewpoint.

Even welding on a spring perch has to be done in such a manner, as to accommodate the original OEM specifications and the original alloys used in it's production. Get it to hot, you burn a hole into the strut body. Don't get the right alloy metallurgy welds and it's becomes a weakened component.

Such after the fact welding, doesn't take in consideration the original assembly process either. All welding is done prior to any seals or fluids being added to the strut body. For good reason as well. Damage the strut or seals it's ruined. Utilizing a specifically designed and manufactured coil over component, is far safer and wiser than engaging in a backyard DIY project.

The Attack Team Hyundai i30N has Hyundai engineering backing and support. It's a track based race car with an approved racing modification, not DOT, MOT & TUV certification. When you start playing around with suspension components and modifying them, you create all sort of unknown issues.

All this has to be considered. You also have to consider your Insurance requirements, let alone you autos warranty. Have an accident due to failure in a suspension component, that was due to improper DIY modification and see if your insurance pays off.

Daily road use brings out the worst in parts, not road racing. You get it wrong, you endanger yourself and others as well. A complete understanding of the entire concept is required before you jump off the cliff, so to speak. That isn't and hasn't happened here.

Not arguing, I'm attempting to discuss all the possibilities either as they unfold or up front. All points must be considered, not just a select few. I don't believe the N-Cars.net forum wants to retain liability for any issue that may arise, due publishment and negligence. It then affects everyone here.@NULLOBANDITOCould you folks get back on topic and stop arguing?

I haven't read through the details, but as pointed out in the video it's been done, and from what I understand @MRunabout wants to do pretty much that.

The question is how, without breaking the OEM shocks.

EDIT: If I'm honest, I'd also love to get my hands on those WTCR Fastback's springs.

I'm making a point about; DOT, MOT, & TUV safety requirements, original OEM construction, purposeful experience, understanding and attempting to look at such a project from a realistic overall perspective. I completely understand the concept but I also know the entire spectrum of issues and ramifications of engaging in such a project. Otherwise, I've been there done that, with a lot of prior first hand knowledge, understanding and experience.

This is not something you can do in your spare time, in your garage, with limited knowledge or a ricers perspective. (no offense intended, it's a colloquialism) please read below.

Urban Dictionary: ricer

(Ricer: from the latin word Ricarius meaning to suck at everything you attempt) A person who makes unecessary modifications to their most often import car (hence the term "rice") to make it (mostly make it look) faster. The most common modifications are (but not limited to): - Huge exhaust that...

You're already aware of the issues that came up with ST Conversion that @Bullet installed & experienced. They were minor even for a reputable manufacturer. This is just some of the small issues that must be contended with. Due diligence hasn't been accomplished or even spoken about. So, I'm doing so with directness and peaceably as before.

Suspension and Chassis - ST-suspension lowering Springs?

Hey there, I'm currently thinking about getting myself some lowering springs for my i30n, not quite sure though which ones to get. Right now leaning towards the ST 20mm ones, cause it's supposed to be the right compromise between comfort, looks and performance. Does anyone have any experience...

Personally, I don't believe the N-Cars.net Forum needs such a liability or as a proponent of such as hypothetical DIY project, considering the lack of overall expertise involved. Again this is part of an overall perspective, I'm referring to directly. Not a horse with blinders viewpoint.

Last edited:

My stock daily driver VN scrapes on some steep driveways and some huge speed bumps if I'm careless and don't pay attention. I can't see significantly lowering the car with spring rates close to stock and me not being extremely annoyed at having to walk my car around every road irregularity. If I lower the car it'll be because I'm going to up the spring rate significantly for performance (with corresponding tires, etc) and resultingly keep the bottom of the car from scraping all the time. What's the maximum spring rate the stock dampers can effectively control and if you up the spring rates significantly what spring perches do you use to hold the springs safely under aggressive driving? There are a bunch of other questions/issues brought up in this discussion already but I would need to have my basic questions answered satisfactorily to even entertain the idea. Fortunately for me the factory setup exceeds my driving skills at the moment so I'll continue trying to improve with my factory warranty in place

Last edited:

Do you track your car, @R Veloster N?

No one is proposing to develop and sell a product based on this concept. It's a DIY project. DIY, by defintion, means taking responsibility, and anyone with the ability to do this project would also have the ability to identify the risks. Have you seen the stuff people do in grassroots motorsports? This is not exotic by any means.

As has been said, the successful application of this same idea on many other platforms and the WTAC fastback N, which can be seen to use weld-on lower collars, demonstrate this can be done. The spring rate value has no effect on the static load transmitted through the spring and perch.

While of course there will be an upper limit to the spring rate that still results in desirable performance, I doubt the limit of controllable spring rate would be below the kinds of spring rates I'd be interested in. The 100% stiffness setting in the ECS 10 controller is extremely hard. Effect of linear spring compared with progressive remains to be seen but could be an issue.

Lowering springs are typically designed with stiffness close to stock. Many people use them and either aren't bothered by the scraping or don't have significant issues. Lowering is not the benefit I care about in this though.

@MRunabout, while I haven't measured the damper travel, I suspect stacking all that up would be too much in our case. This would probably need some form of long upper spring perch part that interfaces with the spring itself lower down, but still interfaces with the damper rod at the rod shoulder. Feel free to direct message me if you'd rather talk offline. I can't seem to message you based on your profile controls.

No one is proposing to develop and sell a product based on this concept. It's a DIY project. DIY, by defintion, means taking responsibility, and anyone with the ability to do this project would also have the ability to identify the risks. Have you seen the stuff people do in grassroots motorsports? This is not exotic by any means.

As has been said, the successful application of this same idea on many other platforms and the WTAC fastback N, which can be seen to use weld-on lower collars, demonstrate this can be done. The spring rate value has no effect on the static load transmitted through the spring and perch.

While of course there will be an upper limit to the spring rate that still results in desirable performance, I doubt the limit of controllable spring rate would be below the kinds of spring rates I'd be interested in. The 100% stiffness setting in the ECS 10 controller is extremely hard. Effect of linear spring compared with progressive remains to be seen but could be an issue.

Lowering springs are typically designed with stiffness close to stock. Many people use them and either aren't bothered by the scraping or don't have significant issues. Lowering is not the benefit I care about in this though.

@MRunabout, while I haven't measured the damper travel, I suspect stacking all that up would be too much in our case. This would probably need some form of long upper spring perch part that interfaces with the spring itself lower down, but still interfaces with the damper rod at the rod shoulder. Feel free to direct message me if you'd rather talk offline. I can't seem to message you based on your profile controls.

Just about everything that has needed to be said, has been regarding the subject.

Frankly and to be completely transparent; I was modifying and racing cars & motorcycles, before either or you were born. Also, this isn't the place to discuss my personal accolades of; racing or my mechanical expertise, which is vast. If you'd like to PM me and ask the same question, I'll be happy to tell you all about them. Be forewarned, make sure you book at least an hour or so to read over them. Additionally, such a comment has no applicability to this discussion and is nothing but a dirt road.

Additionally, such a comment has no applicability to this discussion and is nothing but a dirt road.

Now back to the "Bench Racing;"

Attack i30N Hyundai and Daily Use Comparison;

A purpose built racing car is far different then a daily driver. They're utilized in controlled, optimal conditions, on close corse circuits, Where as a daily driver, is utilize on all sorts of road conditions that are and aren't known, seen or unseen. Under far less controlled and worse than nominal conditions. They have to endure it over and over again, on a daily basis.

Where as a purpose built track car doesn't and is frequent inspected and rebuilt to ensure optimal mechanical condition is maintained. Daily drivers aren't and often neglected by there owners, even those who believe such as yourselves, fail to realize.

Thanks for your comments but you're attempting to the preach to the "experienced and highly qualified ," peanut gallery or choir.

Frankly and to be completely transparent; I was modifying and racing cars & motorcycles, before either or you were born. Also, this isn't the place to discuss my personal accolades of; racing or my mechanical expertise, which is vast. If you'd like to PM me and ask the same question, I'll be happy to tell you all about them. Be forewarned, make sure you book at least an hour or so to read over them.

However, as I have derive from both of you young folks comments, you both have shown a succinct lack of overall knowledge and understanding about the subject your attempting to discuss. You're able to acquire far more from hands on knowledge and experience by regularly performing such work, than attempting to acquire it "Bench Racing "on forums.(No offense intended and I do mean in a peaceable manner )

Now back to the "Bench Racing;"

No one said it can't or hasn't been done by someone with the proper equipment, knowledge and understanding. I'm pleased to be the one to inform your, they most certainly do. There is more than just compression and rebound the springs and perches have to endure and deal with directly.As has been said, the successful application of this same idea on many other platforms and the WTAC fastback N, which can be seen to use weld-on lower collars, demonstrate this can be done. The spring rate value has no effect on the static load transmitted through the spring and perch.

Otherwise talks cheap, anyone can do it. Action and works, speak far louder than words. This is exactly how we all learn, from hands on experience and those who understand such concepts entirely.Someone once said, "by engaging our hands in work keeps us gainfully occupied. Which will ultimately disengage our mouths."

Attack i30N Hyundai and Daily Use Comparison;

A purpose built racing car is far different then a daily driver. They're utilized in controlled, optimal conditions, on close corse circuits, Where as a daily driver, is utilize on all sorts of road conditions that are and aren't known, seen or unseen. Under far less controlled and worse than nominal conditions. They have to endure it over and over again, on a daily basis.

Where as a purpose built track car doesn't and is frequent inspected and rebuilt to ensure optimal mechanical condition is maintained. Daily drivers aren't and often neglected by there owners, even those who believe such as yourselves, fail to realize.

Thanks for your comments but you're attempting to the preach to the "experienced and highly qualified ," peanut gallery or choir.

Last edited by a moderator:

Okay, before this shitstorm continues I believe we just need to accept differences and move along (or just back away).....

@R Veloster N you've made your point and given full details of what and why you think that way.

BUT

this is an open forum and people are free to discuss ideas (good or bad) as much as they like without being berated all the time about why they are wrong (and that is how it looks, intentional or not).

Too much of the Veloster forum posts end up in arguments and we receive multiple reports over "tit for tat" comments. At times threads just get locked or cleaned up as people can't just move on.

Please lets not turn this into another...........this goes for everyone!

Mods are keeping a very keen eye on this type of thing from now on. It is totally unnecessary!

@R Veloster N you've made your point and given full details of what and why you think that way.

BUT

this is an open forum and people are free to discuss ideas (good or bad) as much as they like without being berated all the time about why they are wrong (and that is how it looks, intentional or not).

Too much of the Veloster forum posts end up in arguments and we receive multiple reports over "tit for tat" comments. At times threads just get locked or cleaned up as people can't just move on.

Please lets not turn this into another...........this goes for everyone!

Mods are keeping a very keen eye on this type of thing from now on. It is totally unnecessary!

And if I may add to @loafer-N77 's comments - @R Veloster N mate I do think "plagiarized" is too extreme an accusation in relation to @RameusJH 's posts, unless you have proof that he's taken someone else's work and claimed it as his own. Even if you believe he has, please just take it offline so we can all concentrate on the reason we're here - our cars and our enjoyment of them. Keep it civil, people.

@Tom Vanlimbergen I hear you, but people will always experiment and push the boundaries. It is human nature. It is how we evolve. I watched the Space Shuttle Challenger crash and burn just before I hopped on a bus bound for my first day of high school. There will always be collateral damage in the name of progress so let's not get too precious. The Industrial Revolution without doubt resulted in wholesale injury and death. But without it we would not be driving N cars.

I'm not posting this to inflame further argument or debate (please don''t respond here and further derail the thread, just PM me if you absolutely feel the need), just in the hope that we can put this above mess to bed and celebrate the diversity of ideas. Let the DIY-ers do what they want to do and at their own risk and take it or leave it. Take responsibility for your own actions even if you're acting on someone else's advice - it's always your choice in the end.

@Tom Vanlimbergen I hear you, but people will always experiment and push the boundaries. It is human nature. It is how we evolve. I watched the Space Shuttle Challenger crash and burn just before I hopped on a bus bound for my first day of high school. There will always be collateral damage in the name of progress so let's not get too precious. The Industrial Revolution without doubt resulted in wholesale injury and death. But without it we would not be driving N cars.

I'm not posting this to inflame further argument or debate (please don''t respond here and further derail the thread, just PM me if you absolutely feel the need), just in the hope that we can put this above mess to bed and celebrate the diversity of ideas. Let the DIY-ers do what they want to do and at their own risk and take it or leave it. Take responsibility for your own actions even if you're acting on someone else's advice - it's always your choice in the end.

Thank you for both your perspectives and comments. I'll most certainly take them under advisement. I have or harbor no animosity towards anyone. I believe I've demonstrated it quite vigorously.

I simply want to bring all points to bear in such a discussion. I've seen such projects go entirely wrong.

I simply want to bring all points to bear in such a discussion. I've seen such projects go entirely wrong.

Last edited: